In SP Technologies we use cutting edge machinery along with exotic materials such as titanium, ceramic, aluminum, carbon, zylon and more, generating futuristic methods and objects.

MATERIALS

01

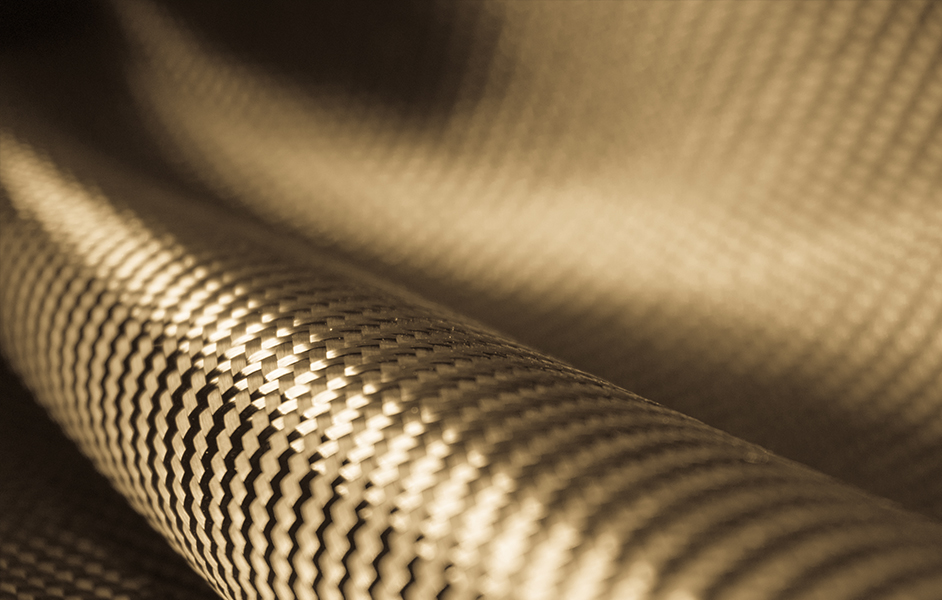

Zylon is a trademarked name for a range of thermoset liquid crystalline polyoxazole. In generic usage, the fiber is referred to as PBO. Zylon has 5.8 GPa of tensile strength, which is 1,6 times that of Kevlar. Additionally Zylon has a high Young’s modulus of 270 GPa , meaning that it is stiffer than a steel. Like Kevlar, Zylon is used in a number of applications that require very high strength with excellent thermal stability. As has been the case since 2001, Zylon tethers are used in Formula One to affix the wheel to the chassis, thus preventing the wheel from ejecting into a crowded area in the event of an accident which causes the wheel to become airborne. Starting in the 2007 season, the driver’s cockpit must now be clad in special anti penetration panels made of Zylon.

02

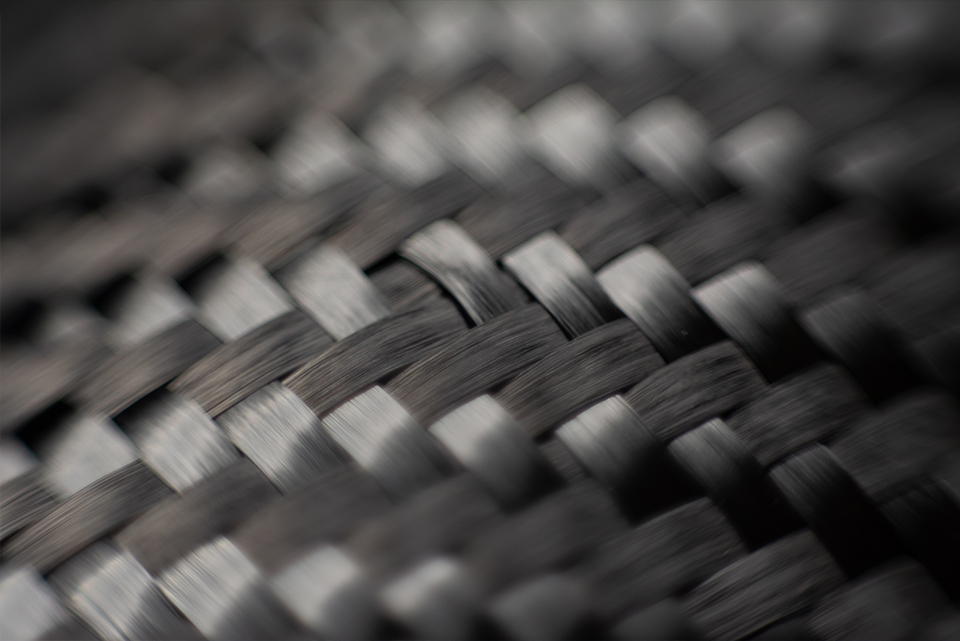

While metal and metal alloys are still critical to automotive design, automakers are finding innovative ways to leverage plastics and composites into their designs to help reduce vehicle weight and improve efficiency. Carbon fibers are fibers about 5 to 10 micrometers (0.00020 0.00039 in) in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages including high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, and motorsports, along with other competition sports. However, they are relatively expensive when compared with similar fibers, such as glass fibers or plastic fibers.

03

Kevlar

Kevlar® fibers bring together temperature resistance, strength, reinforcement and other properties that can help improve filters, belts, gaskets and other automotive components. Kevlar brand fibers help improve the safety, performance and durability of automotive components for a wide variety of vehicles, from passenger cars and light trucks to professional race cars. It is not uncommon for a new vehicle to have several crucial parts that employ products made of Kevlar aramid fibers. Kevlar brand fiber helps improve the safety, performance and durability of automotive components such as automotive hoses and automotive belts for a wide variety of vehicles, from passenger cars and trucks to professional race cars.

04

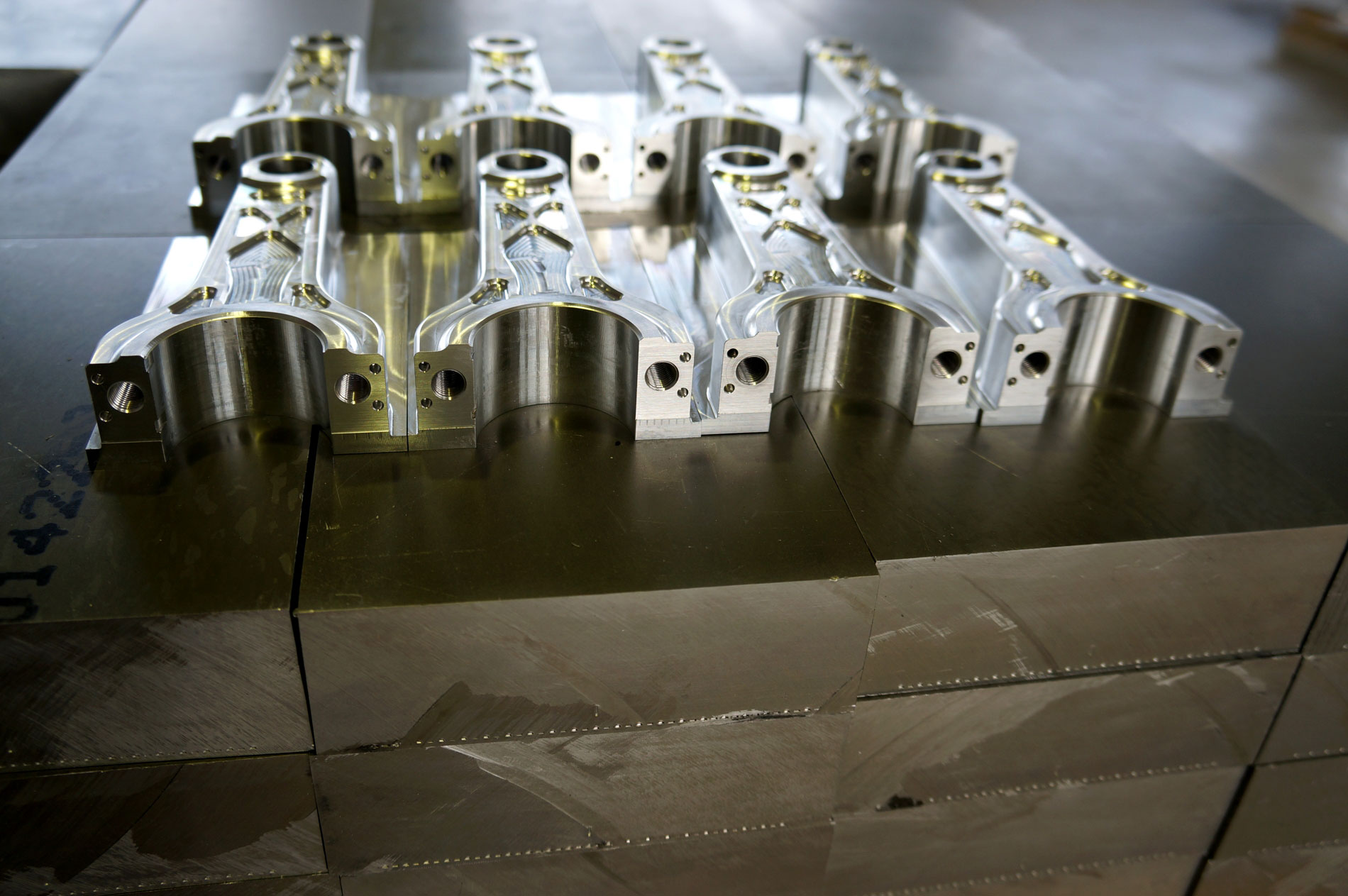

In strength to weight ratio, Tennalum out performs nearly all other engineering alloys in existence (33% better strength to weight performance than 7075, and 28% better performance than 6Al 4V Grade 5 Titanium). However, due to its higher cost (3 4 times that of 6061) and limited availability, it has seen very little commercial use. But for many applications there is no better alloy, not even Titanium.

05

The new material, the amorphous metal dubbed SAM2X5 630 is made by using metallic glass matrix composites (MGMC) to replace a number of atoms in standard steel’s crystal like structure. In effect, this amalgam of materials creates a new version of steel that has great resilience to shock, and is able to bounce back into shape, rather than bend or tear as ordinary steel may do under high pressure. The new steel alloy can stand up to pressures of over 12.5 giga Pascals (more than 1,8 million psi, or about 125,000 atmospheres) without being permanently deformed. This is the highest recorded elastic limit for any steel alloy.